HOME > Maintenance > Sterilization・Disinfection

Sterilization・Disinfection

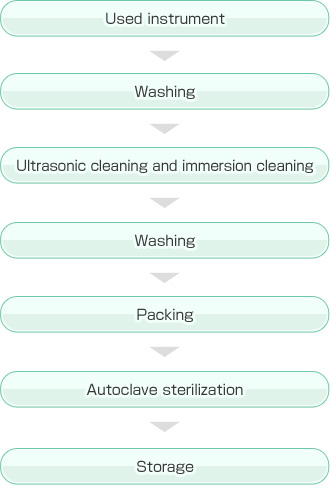

Basic Autoclave Sterilization Cycle

*Note: Products may differ, so check the catalogue, attachments, and user manuals.

Autoclave Sterilization

Heat in saturated steam at a suitable temperature and pressure inside the chamber, and the water content that forms accelerates the protein coagulation to kill the microorganisms.

●Advantages

- Temperature rise is fast, and due to the steam permeability the effects are deep

- Highly effective on spores

- No residual toxins

- Low running costs (economical)

●Disadvantages

- Equipment misshaping due to wet heat

- Reduced sterilization effectiveness if air is not completely evacuated

- Non-heat-resistant equipment cannot be sterilized

●Precautions

Steam is arranged to flow easily from top to bottom so that the equipment is not overly jammed into the sterilization chamber.

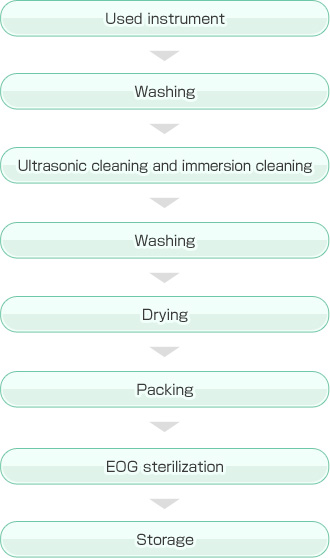

Basic EOG Sterilization Cycle

*Note: Products may differ, so check the catalogue, attachments, and user manuals.

EOG Sterilization

Sterilization method that eliminates bacteria by alkylating the proteins that comprise the microorganisms using ethylene oxide gas (EOG).

●Advantages

- Low-temperature sterilization is possible, so there is no change in quality due to heating

- Non-heat-resistant equipment can also be sterilized

- EOG has high permeability, so sterilization of packages and sealed products is also possible

●Disadvantages

- Comparatively long sterilization time

- Required costs are high

- Time is required for aeration (Processing to reduce gas concentration in the chamber after sterilization.)

- High residual toxicity

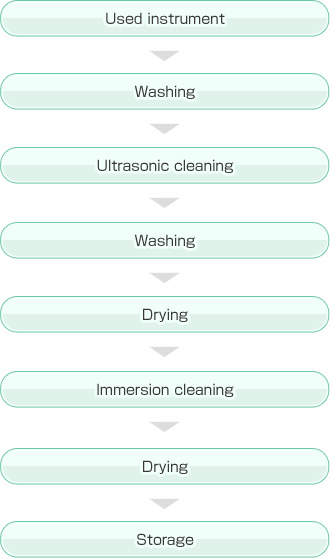

Basic Chemical Disinfection Cycle

Chemical Disinfection

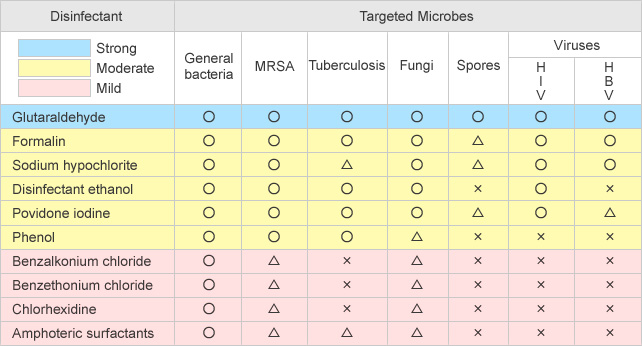

Many of the commercial disinfectants are considerably low quality with expressions like "bacteria elimination" and "pasteurization".

Use of broad-spectrum antimicrobials and high-level disinfectants with strong microbe killing power for the chemical disinfection of equipment is recommended.

Glutaral products (glutaraldehyde) is a liquid disinfectant that can kill nearly all microorganisms.(See diagram below.)

This method requires no special equipment, and can be introduced easily to non-heat-resistant equipment sterilization as it is comparatively inexpensive.

In Japan, the actual concentration used is a dilution of 2% to 3.6%.

The minimum effective concentration of glutaral is 1% to 1.5%, and at normal use with dilutions of 2%, the fluid must be replaced approximately weekly.

According to the notice from METI dated March 2005, if implementing sterilization using glutaral products, regulations must be displayed to implement effective measures such as ventilation when the glutaral concentration in the workroom exceeds 0.06ppm.

WHO uses immersion in glutaral products for 30 minutes minimum, but recent information describes how all pharmaceutical companies use the unified standards described below.

1)Equipment with adhering body fluids: 1 hour min.

2)Equipment without adhering body fluids: 30 minutes minimum.

Dental clinics cannot avoid the adhesion of body fluids (including saliva), so immersion for 1 hour minimum is recommended.

*Note: Products may differ, so check the catalogue, attachments, and user manuals.

*Note: Products may differ, so check the catalogue, attachments, and user manuals.